Hello all,

Well I on vacation till next year and have time to work on my build. I have put shellac over the edge of the guitar and routed the binding channel with no problems.

This is great because I was relly nervous about it.

This is great because I was relly nervous about it.

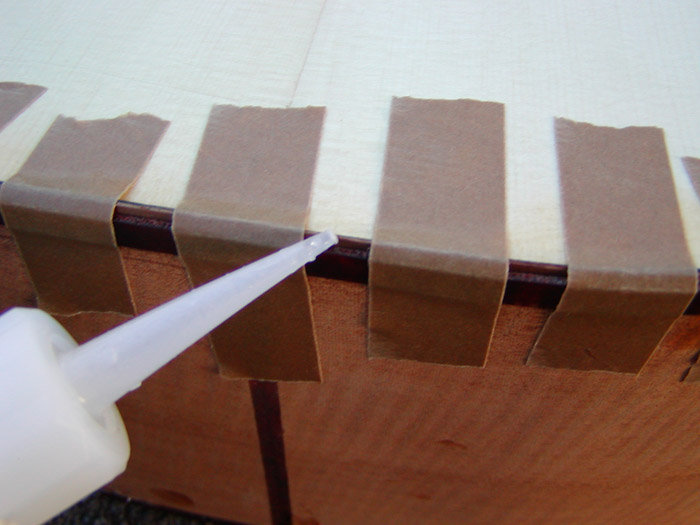

Next comes the installation of the binding itself. I have the stewmac balck 0.009" binding and have heated it to a form that is very close to my guitar shape. It is not perferct but very close. I am going to use the Weldon cement from stewmac for the large radius areas but will probably use CA for the waist and the cutaway.

I got the binding because I thought it would be forgiving visually because of it's thickness. I found that it was very hard to bend and keep bent to what I wanted. So the CA method came to mind to work in small areas, spray accelerator lightly (or baking soda), then wick in water thin CA glue to bond the binding where I want it and when I want it.

The only question I have on the CA method is do I put shellac in the channel prior to putting the accelerator and glue? I have searched the forum and am confused on this point. Again I have shellac over the top and sides already when I routed the channel....do I need it in the channel as well to prevent staining?

Also, if you have any tips or links to individuals methods here on this subjedct this would be great.

Thanks again!